Membrane Area | 262ft2 | 24.3m2 | |

|---|---|---|---|

Standard Flow Channel Size(ID) | 0.09in | 2.4mm | |

Membrane Housing Material | Fiberglass shell, Fluororubber/EPDM sealing, Duplex stainless steel SS2507 interface, Thermoplastic end caps | ||

Membrane Material | α-Al2O3 | ||

Standard Membrane Pore Size | 0.03 microns | 30 nanometers | |

Membrane Module Placement During Operating | |||

Weight(+/-10lbs;5Kg) | Shipping Weight | 187lbs | 85Kg |

Full Water Weight | 275lbs | 125Kg | |

Membrane Module Water Holding Capacity | 8.2gal | 31L | |

Membrane Module Model | QM UF -24 | ||

|---|---|---|---|

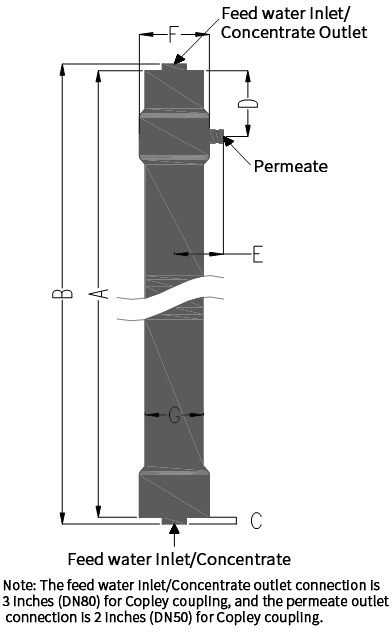

Module Length | A | 74.39in | 1889mm |

B | 75.75in | 1924mm | |

C | 0.38in | 9.65mm | |

Lateral End Cap Dimensions | D | 11.58in | 294mm |

E | 6.22in | 158mm | |

Module Diameter | F | 10.12in | 257mm |

G | 8.41in | 213mm | |

Operating Parameters | |||

Filtration Flux | 85~300GFD | 150~500l/m2/hr | |

Filtration Flow Rate | 15~55GPM | 3.5~12m3/hr | |

Filtration Mode | Dead-end or cross-flow filtration, with a maximum flow rate of 150 GPM (34 m³/hr), Internal pressure vessel | ||

Backwash Flux | 130~500GFD | 220~850l/m2/hr | |

Flushing | From 1 to 3 times the filtration rate up to the maximum cross-flow rate. | ||

Operating pH Range | 2~12 | ||

Chemical Cleaning pH Range pH(<45℃) | 1~13 | ||

Maximum Operating Pressure@77℉/25℃ | 150psi | 10bar | |

Maximum Transmembrane Pressure Differential @95℉/35℃ | 100psi | 7bar | |

Operating Temperature Range | 32~113℉ | 0~45℃ | |

Maximum Temperature Change Rate | 10℃/min | ||

Note:

The feed water Inlet/Concentrate outlet connection is 3 inches (DN80) for Copley coupling, and the permeate outlet connection is 2 inches (DN50) for Copley coupling.

Advantages:

Compared to organic membranes, ceramic membranes have significant advantages

Water flux is up to 4 to 7 times higher than that of organic membranes

Tolerance to suspended solids is higher than that of organic membranes

Strong chemical resistance and chemical stability

Strong membrane recovery capability

Longer membrane service life

Good and stable water quality of production

Easy to maintain

Application Fields:

Ceramic membranes have been widely used in industrial fields, including:

Pre-treatment for lithium extraction from brine

Industrial/Municipal wastewater reuse

Pretreatment for NF/RO

Direct treatment of high turbidity surface water

Cost-effectiveness:

Significantly increased service life and lower membrane replacement costs

Low failure rates, greatly reducing operational risks

Relatively reduced operating costs, including lower consumption of chemicals

Less initial investment, stable water quality protects downstream process equipment, extending their service life