Home > Business > Products > Reverse Osmosis Membrane > High-pressure Loose Reverse Osmosis membrane

Home > Business > Products > Reverse Osmosis Membrane > High-pressure Loose Reverse Osmosis membrane | Model | Area/Piece | Application Pressure | Grid thickness | Water yield GPD/m3/d | Material | Boron Removal Rate % | Standard Desalination Rate % |

|---|---|---|---|---|---|---|---|

| SL Lithium RO 8040 HR 40 | 370ft2/34.4m2 | 1200psi | 34mil | 10500/39.7 | FRP | 65 | 92 |

Note:

1. Membrane flux and desalination rate are based on the following test conditions: 32000ppmNaCl,600psi(41.3bar),77℉(25℃),pH8,15% recovery rate.

2. The water yield of a single element may vary within a range of ±25%.

3. Minimum desalination rate: 80%.

4. The stable desalination rate is normally achieve within 36-72 hours of continuous operation, depending on feeding features and operating conditions.

5. Sales specifications for this product may change slightly in accordance with design optimization

6. Guaranteed effective area: ±5%.

| Model | size(in./ cm.*) ABC | Packing weight LBS/Kg |

|---|---|---|

| SL Lithium RO 8040 HR 40 | 40.0/101.6 1.125/2.86 7.9/20.1 | 35/16 |

Note:

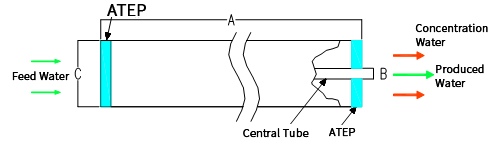

Membrane element fit into pressure vessels with engineered internal diameter of 8 in (20.3cm). *1in=2.54cm

| Operating Flux Range | 8-34LMH |

| Maximum Operating Pressure1 | 1200psi (82.7bar) |

| Maximum Withstand Temperature2 | 122°F (50°C) |

| Maximum Withstand pH Value | Continuous Operation2:3 – 10 CIP:2 – 12 |

| Maximum Pressure Drop | 15psi (1.0bar) |

| Maximum Chlorine Tolerance3 | <0.1 ppm |

| Feeding Water Quality Requirements | NTU < 1;SDI15 < 5 |

Note:

1. If the temperature is higher than 95°F (35°C), please contact us to determine the specific solution.

2. The highest operating temperature is 95°F (35℃) when pH value is higher than 10.

3. Under certain circumstances, free chlorine and other oxidizing agents can cause premature failure of membranes, therefore, it is recommended to remove free chlorine before it contacts with membranes.

When the membrane system is ready to be commissioned, the membrane treatment system needs to be started up correctly to prevent damages to membrane elements caused by the overflow of feeding water and the hydraulic shock. The correct initiating sequence helps to ensure that the system’s operating parameters align with design requirements, so that the quality and quantity of produced water through the system reach designed objectives.

Before the membrane system is initiated for the first time, pretreatment system debugging, elements loading, instrumentation debugging and calibration and ancillary equipment system debugging and so on shall be completed.

Please contact us for more information.

For more information, please contact us

During start-up, shutdown, cleaning, etc., to prevent potential damaged to membranes, any sudden changes of pressures or of crossflow flow in membrane elements shall be avoided. During start-up, it is suggested to follow the undermentioned procedures to gradually transit the system from shutdown to operating:

Feeding pressure should be gradually escalated over a period of 30 ~ 90 seconds.

The set peak of crossflow velocity should be gradually achieved over a period of 30~ 60 seconds.

For more information, please contact us

Once the membrane element is moisturized, it should always be kept moist.

If users failed to strictly follow the set operating limitations, the warranty will be null.

If the system need to be shut down for an extended period of time, it is recommended to immerse the membrane elements in protective solution to prevent microorganisms.

The user shall be responsible for any damages to the membrane elements caused by using incompatible chemicals, lubricants, etc.

The maximum pressure drop a single pressure vessel can tolerate is 50psi (3.4bar).

Under all circumstances, backpressure must be avoided on the production side of the membrane system.

For more information, please contact us