Global Business, BICHEM Group

Amid the rapid growth of the new energy industry, lithium resources—often referred to as “white oil”—are becoming increasingly strategic. Despite the sufficient lithium reserves worldwide, lithium extraction from brine has long been constrained by high magnesium-to-lithium ratios, low lithium concentrations, and harsh operating environments. As a result, lithium extraction from salt lakes has faced the persistent dilemma of being “resource-rich but difficult to utilize.” In particular, the efficient separation of lithium, sodium, and potassium ions in lithium precipitated mother liquor has been a critical bottleneck limiting the economic viability of salt lake lithium extraction. Today, a green and efficient solvent extraction and separation technology independently pioneered by BiChem’s China team has successfully overcome this world-class challenge, injecting a key driving force into the high-quality development of the salt lake lithium extraction industry.

Recovery from lithium precipitated mother liquor represents the “last mile” of salt lake lithium extraction, directly determining resource utilization efficiency and overall economic returns. Conventional lithium extraction technologies generally suffer from poor selectivity, low separation efficiency, high acid and alkali consumption, and severe loss of separation media when dealing with monovalent ions such as lithium, sodium, and potassium. These issues not only lead to significant lithium losses but also drive up production costs and intensify environmental pressures, which limits the salt lake lithium extraction industry for a long time. Even though, in theory, the cost of salt lake lithium extraction is only about half that of hard-rock mining, large-scale and efficient development has remained elusive. As a result, the world’s lithium self-sufficiency rate has been only around 30%, with heavy reliance on imports of Australian spodumene and South American brine resources.

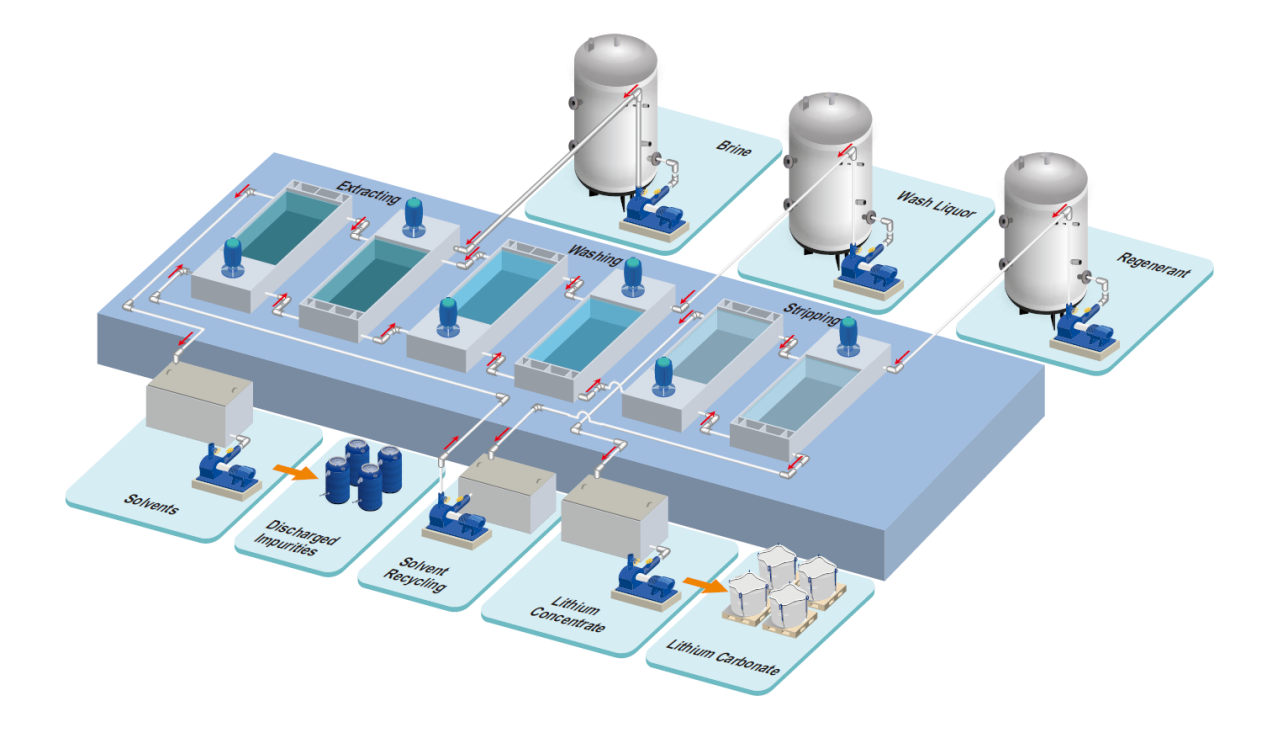

To address this challenge, BiChem’s China team has achieved a major breakthrough by developing a green and highly efficient solvent extraction and separation technology for lithium recovery. The core innovation lies in a newly designed and synthesized proprietary lithium-selective extractant, capable of precisely identifying and capturing lithium ions from brine, enabling efficient separation of lithium from sodium and potassium ions. This breakthrough systematically resolves multiple challenges associated with traditional extraction systems, including environmental performance, operational safety, and cost control. Compared with conventional technologies, the advantages are significant: overall lithium ion recovery is increased by 15%–20%, with lithium recovery rates exceeding 98%; total production costs are reduced by 30%; and both water and energy consumption are more than 30% lower than industry benchmarks, fully aligning with green and low-carbon development principles.

The true value of technology lies in industrial application. At present, the world’s first industrial-scale demonstration line for extracting lithium from lithium precipitated mother liquor via solvent extraction—capable of producing tens of thousands of tonnes of battery-grade lithium carbonate—has been completed and put into operation in Qinghai Province. The project has generated more than $86 million in additional output value, validating the technology’s stability and scalability through tangible results. Expert evaluations confirm that the technology has reached an internationally leading level. Its successful application not only fills a critical gap in capabilities for efficient separation of lithium precipitated mother liquor, but also enables certain projects—despite their less favorable natural resource endowments—to gain a global cost advantage in salt lake lithium extraction through technological strength. Comprehensive costs are reduced by 30% compared with traditional routes, effectively breaking the low-cost lithium supply dominance long enjoyed by South American salt lakes based on natural resource advantages.

Behind this core technological breakthrough lies the coordinated support of a diversified salt lake lithium extraction technology system and a well-developed industrial ecosystem. To precisely adapt to the complex characteristics of different salt lake brines, the industry has established a full-chain technology matrix centered on adsorption methods, membrane separation, and multi-technology integrated processes. As a leading enterprise specializing in full-process solutions for salt lake lithium extraction, BiChem not only possesses comprehensive capabilities spanning technology R&D, process design, engineering construction, and operations and maintenance, but also has extensive experience in commercial deployment. The company has successfully delivered and operated multiple salt lake lithium projects globally. Together with its breakthrough solvent extraction and separation technology, these capabilities form an efficient complement, providing comprehensive and highly stable technical support across key stages such as brine pretreatment, deep impurity removal, and cascading resource recovery, thereby maximizing the effectiveness of lithium precipitated mother liquor separation technology.

Building on its technological foundation and industrial practice, BiChem is actively promoting this solution on a global scale by combining strong economic performance with environmental sustainability. By exporting mature full-process lithium extraction technologies, standardized engineering services, and sustainable operating models to salt lake development projects, BiChem aims to provide globally applicable solutions that balance technological advancement with commercial viability. These efforts support the efficient extraction and green utilization of lithium resources worldwide, contributing to supply chain security and low-carbon development in the new energy industry.

This technological breakthrough is profoundly reshaping global lithium supply landscape. As the technology is further deployed, previously undevelopable, high-difficulty salt lake resources will be transformed into economically viable supplies. By 2025, the incremental output from upgraded salt lake lithium projects worldwide is set to expand the overall lithium carbonate equivalent (LCE) supply significantly. By improving recovery efficiency and lowering production costs, the technology has the potential to ease structural supply pressures in the global lithium market and support a more diversified and resilient supply chain. The maturation of efficient lithium precipitated mother liquor separation technology will help stabilize lithium price benchmarks, providing cost-controlled raw material security for the projected 630 GWh of energy storage lithium battery shipments in 2025, and driving continued cost reduction and efficiency gains across the new energy sector.

From the perspective of the global energy transition, this breakthrough in the efficient separation of lithium, sodium, and potassium ions from lithium precipitated mother liquor not only resolves challenges in salt lake lithium extraction, but also offers an effective solution for the development of high-difficulty salt lake resources worldwide. Looking ahead, with continued technological iteration and deeper integration with adsorption, membrane separation, and other methods, salt lake lithium extraction will move toward greater efficiency, sustainability, and intelligence.

Disclaimer: The content provided by Bichemical Technology Limited or BICHEM Group is for informational purposes only. Sharing requires retaining the original link. All BICHEM Research content is protected, and reproduction, distribution, or publication in any form is prohibited without prior written permission. For authorization, contact info@bichemcial.org. The information is for reference only and not direct decision-making advice. Users are responsible for their own decisions, and BICHEM Research assumes no liability for any outcomes.